|

| British Standard Washbasin or Lavatory. Not a toilet. |

TABLE MAKER Occupation. Sanitaryware caster specialising in making tables, which are lavatories, which are washbasins but they are not toilets.

TABLEWARE Crockery used on the table during the serving of meals - breakfast, lunch, tea and dinner. Used in serving, and eating food, including serving dishes, plates, bowls etc. Includes dinnerware and tea-ware. For both formal and casual dining.

TAILINGS Residue of a material that will not pass through a sieve or lawn.

TALC Material. Used in the ceramic recipe. A soft mineral that is a basic silicate of magnesium. Has a soapy feel.

TALL CUP A cup which is tall (!) Opposite to low cup. Tends to keep hot liquids hotter for longer. Most favoured in the UK and cold climes.

TANNIN Material. Defloculant for clay slip. A complex organic compound produced in trees.

TAWS Dialect. Marbles used for games.

TAYTERED Dialect. Tired. Jiggered.

TEA Most potters thrive on tea. Tea is drunk is copious amounts during the potter's day but tea is also the main meal of the day, actually dinner. Dinner could be taken at teatime for tea, after work. This is not afternoon tea which is between lunch or dinner and tea or dinner. Potters can, of course, have a dinner-for-tea which is the evening meal. In at least one potter's household the question would arise 'Are we having a dinner-for-tea?' See dinner or go here> but don't get confused! Then you might need tea (the drink , not the meal) to get over it!

TALC Material. Used in the ceramic recipe. A soft mineral that is a basic silicate of magnesium. Has a soapy feel.

TALL CUP A cup which is tall (!) Opposite to low cup. Tends to keep hot liquids hotter for longer. Most favoured in the UK and cold climes.

TANNIN Material. Defloculant for clay slip. A complex organic compound produced in trees.

TAWS Dialect. Marbles used for games.

TAYTERED Dialect. Tired. Jiggered.

TEA Most potters thrive on tea. Tea is drunk is copious amounts during the potter's day but tea is also the main meal of the day, actually dinner. Dinner could be taken at teatime for tea, after work. This is not afternoon tea which is between lunch or dinner and tea or dinner. Potters can, of course, have a dinner-for-tea which is the evening meal. In at least one potter's household the question would arise 'Are we having a dinner-for-tea?' See dinner or go here> but don't get confused! Then you might need tea (the drink , not the meal) to get over it!

TEA FOR TWO SET

TEASER Equipment. Used in figuremaking. May be specific to Wedgwood. Specially-made metal tool with flat springy ends. Used by figuremakers to lift clay 'relief' forms from the porous figure mould. Figures raised clay ornament decoration on Jasper ware. See the process here> https://www.youtube.com/watch?v=1Vi5mg5iH88

TEASET COMPOSITIONS In 1971 'The British Pottery Promotion Service Ltd' published "usual set compositions." It was quite specific! "It is often puzzling to the homemaker to know just what is needed in the way of tableware, cutlery glass and linen. Certainly if you plan any formal entertainment you will need a dinner service - which need not be costly - for at least six people." "You will also find you need a tea service. There is a vast range of English Tableware both traditional and modern from which to select the pattern of your choice."

18 piece

6 teacups and saucers

6 tea plates

21 piece

6 teacups and saucers

6 tea plates

1 sugar basin

1 milk jug

1 bread and butter plate

22 piece

As 21 piece but with a covered sugar box

40 piece

12 teacups and saucers

12 tea plates

1 sugar basin

1 milk jug

2 bread and butter plate

|

| Royal Albert teaset (6 piece) in Old Country Roses pattern |

TEA SERVICE Essentially the same as a teaset.

TEAWARE Not dinnerware. Used for taking tea, not dinner (when you would obviously use dinnerware.) But can be regarded as Tableware.

TECHNICAL CERAMICS Technical ceramics are characterised by their high mechanical strength, durability and heat resistance as well as by their unique electrical properties. They are therefore indispensable in a wide range of applications for everyday life. Examples include:

◦ Improvements in security (e.g. crash/airbag sensors, fire protection, military protection)

◦ Improvements in health (e.g. prostheses, pacemakers, cochlear implants)

◦ Improvements for the environment (filter systems, e.g. catalytic converters, high pressure fuel injection, thermostats, insulation)

TEMPERING Weathering. Raw ball clay or fireclay is weathered or tempered before use. The clay is stored outside in huge mounds (a clay bank) to allow the weather (rain) to leech out the soluble salts from the clay mass. China clay is however not weathered since it needs to be kept clean and free from impurities. China clay is usually stored undercover

TEMPERING WATER Water added to dry clay to return it to a fully plastic and malleable condition.

TENMOKU Material. Stoneware glaze used by craft potters. Deeply coloured by iron oxide. Dark coloured, deep brown, sometimes with a surface that resembles oil spots. These glazes produce lustrous results that vary in colour from yellow, green, rust red, dark plum, brown and black. Gorgeous!

TENSILE STRENGTH The resistance of a material to being torn apart by tension or pulling.

TERTIARY AIR Used during firing. In reducing kilns (Eg: for the production of blue bricks and tiles) Introduced into the firing cycle to burn up combustibles in waste gases. Reduces smoke.

TERRACOTTA Type of unglazed pottery with a particular recipe and requiring particular firing conditions. Fired at 1150°C - 1250°C. Literally 'burnt earth.' and typified by its unique red terracotta colour caused by its high Iron content. Excellent material for the production of decorative ornament in architecture. Frequently used as a dressing on brick buildings and is therefore usually unglazed. Like stoneware the smooth texture can be modified, by addition of grog (coarse material), to give a much rougher finish.

TEST PIECES Trial pottery pieces designed to show the potter the different results from different recipes of clay or glaze or colour after firing.

TECHNICAL CERAMICS Technical ceramics are characterised by their high mechanical strength, durability and heat resistance as well as by their unique electrical properties. They are therefore indispensable in a wide range of applications for everyday life. Examples include:

◦ Improvements in security (e.g. crash/airbag sensors, fire protection, military protection)

◦ Improvements in health (e.g. prostheses, pacemakers, cochlear implants)

◦ Improvements for the environment (filter systems, e.g. catalytic converters, high pressure fuel injection, thermostats, insulation)

TEMPERING WATER Water added to dry clay to return it to a fully plastic and malleable condition.

TENMOKU Material. Stoneware glaze used by craft potters. Deeply coloured by iron oxide. Dark coloured, deep brown, sometimes with a surface that resembles oil spots. These glazes produce lustrous results that vary in colour from yellow, green, rust red, dark plum, brown and black. Gorgeous!

|

| Example of a Tenmoku glaze |

TENSILE STRENGTH The resistance of a material to being torn apart by tension or pulling.

TERTIARY AIR Used during firing. In reducing kilns (Eg: for the production of blue bricks and tiles) Introduced into the firing cycle to burn up combustibles in waste gases. Reduces smoke.

TERRACOTTA Type of unglazed pottery with a particular recipe and requiring particular firing conditions. Fired at 1150°C - 1250°C. Literally 'burnt earth.' and typified by its unique red terracotta colour caused by its high Iron content. Excellent material for the production of decorative ornament in architecture. Frequently used as a dressing on brick buildings and is therefore usually unglazed. Like stoneware the smooth texture can be modified, by addition of grog (coarse material), to give a much rougher finish.

TEST PIECES Trial pottery pieces designed to show the potter the different results from different recipes of clay or glaze or colour after firing.

THA KNOWST Dialect. You know if you know tha knowst. If you see what I mean. Thanks to Phil Rowley, July 2021, for this one!

THE POTTERIES

back to top>

THERMAL CONDUCTIVITY The rate at which heat passes through a material as measured by its rise in temperature.

THERMAL EXPANSION The increase in the volume of a material as its temperature is increased.

THERMAL EXPANSION and GLAZE FIT The relationship between the thermal expansion of the body and the glaze. Matching the thermal expansion of the pottery body to that of the glaze so as to prevent a glaze fault called crazing. To prevent crazing the glaze should normally be held in compression. If the glaze is expanding or contracting more than the body to which it is attached, something has to give way! And crazing results. Thermal expansion and contraction are not to be confused with fired shrinkage which occurs during firing.

THERMAL SHOCK A variation in temperature which causes tension in a material. Frequently causes breakage. Common in brittle materials such as ceramics. Also found during the pottery firing process. Cracking can occur if cooling, after firing, occurs too quickly. In the pottery industry this is called dunting, and the resultant faults are called dunts. To avoid dunting, cooling rates of less than 50°C per hour are used by potters.

THERMOCOUPLE Equipment. Part of a bottle oven or modern kilns. Electronic method of high temperature measurement. Based on tiny electric current produced at the junction of two dissimilar metals in a wire when the wire is heated.

THIMBLE Kiln furniture. Manufactured by pressing refractory clay into moulds. The conical base of one thimble fits into the open top of the thimble below so that a series, or tower, of thimbles make one upright support. Three of these towers, in a triangular formation, create the individual supports for flatware, in a saggar, for glost firing.

'Thimbles were used during the times of bottle oven firing. During glost firing they were used to separate plates to prevent the glaze fusing them together. The plate rests on the little pointed bit to make smallest possible mark on the glaze. There were usually three sets of thimbles around a plate, held in place in the saggar by a blob of clay.' This explanation kindly supplied by Angela Lee, Manager, Gladstone Pottery Museum, October 2017.

THE POTTERIES

~~~~~ THE POTTERIES ~~~~~

The six towns, north to south, of Tunstall, Burslem, Hanley,

Stoke-upon-Trent, Fenton and Longton

are collectively known as "THE POTTERIES"

of North Staffordshire, England.

Stoke-upon-Trent, Fenton and Longton

are collectively known as "THE POTTERIES"

of North Staffordshire, England.

One city called Stoke-on-Trent with seven town halls (two in Burslem),

but no cathedral, and named after its main industry. Unique.

but no cathedral, and named after its main industry. Unique.

The Potteries, 1950

back to top>

THERMAL CONDUCTIVITY The rate at which heat passes through a material as measured by its rise in temperature.

THERMAL EXPANSION The increase in the volume of a material as its temperature is increased.

THERMAL EXPANSION and GLAZE FIT The relationship between the thermal expansion of the body and the glaze. Matching the thermal expansion of the pottery body to that of the glaze so as to prevent a glaze fault called crazing. To prevent crazing the glaze should normally be held in compression. If the glaze is expanding or contracting more than the body to which it is attached, something has to give way! And crazing results. Thermal expansion and contraction are not to be confused with fired shrinkage which occurs during firing.

THERMAL SHOCK A variation in temperature which causes tension in a material. Frequently causes breakage. Common in brittle materials such as ceramics. Also found during the pottery firing process. Cracking can occur if cooling, after firing, occurs too quickly. In the pottery industry this is called dunting, and the resultant faults are called dunts. To avoid dunting, cooling rates of less than 50°C per hour are used by potters.

THERMOCOUPLE Equipment. Part of a bottle oven or modern kilns. Electronic method of high temperature measurement. Based on tiny electric current produced at the junction of two dissimilar metals in a wire when the wire is heated.

THIMBLE Kiln furniture. Manufactured by pressing refractory clay into moulds. The conical base of one thimble fits into the open top of the thimble below so that a series, or tower, of thimbles make one upright support. Three of these towers, in a triangular formation, create the individual supports for flatware, in a saggar, for glost firing.

'Thimbles were used during the times of bottle oven firing. During glost firing they were used to separate plates to prevent the glaze fusing them together. The plate rests on the little pointed bit to make smallest possible mark on the glaze. There were usually three sets of thimbles around a plate, held in place in the saggar by a blob of clay.' This explanation kindly supplied by Angela Lee, Manager, Gladstone Pottery Museum, October 2017.

Children, at one time, would play with these thimbles and called them 'ice cream cones'. They were found in lots of places in the Potteries particularly in shraff tips, in and around potbanks and even in domestic gardens.

|

| Used thimbles showing how they slot into each other Thimbles can only be used once. Photo: Courtesy of Chris Morris Date: Oct 2017 |

|

| Maddocks Improved Thimble Patent 1908 |

THIMBLE DIE PRESS Equipment. A machine in a specialist kiln furniture workshop for pressing refractory clay dust into thimbles.

THIMBLE PICKER Occupation. The operative who sorts and arranges thimbles for use by glost placers during placing prior to firing.

THIRDS Faulty pottery. The description given for a classification of the quality of pottery ware. It signifies that the ware is well below the usual best standard, and not even good enough to fall within the description of seconds. But better than lump.

The description or classification of the quality of pottery ware - the eight (or more) grades of pottery quality:

THIRTING Process. During ball clay mining. Cutting ball clay into blocks about 9 inches cube.

THIXOTROPY A description of the flow characteristics of clay slip. The property exhibited by the slip which becomes fluid when stirred or shaken and returns to the semi-solid state when standing.

THOB Potteries dialect word. Part of a bottle oven. The Hob. Just above the glut arch. "Put thee lobby on thob fur cape eat ot, duck." But note that it is not where you would cook breakfast. This was done directly on the fire, in the blazing mouth of the oven, using a British Standard No.8 shovel as the frying pan!

THOD Dialect word. Thump. Bump. Crunch. Bang. Wallop. Things that go bump in the night.

THOROUGH REPAIR Process. In a bottle oven. Almost a complete rebuild of the oven bottoms, ash pit and hob, bags and flues. Since production could be lost during a thorough repair then it was usually carried out at weekends.

THRAPE Thrash.

|

| Thimble die press |

THIMBLE PICKER Occupation. The operative who sorts and arranges thimbles for use by glost placers during placing prior to firing.

THIRDS Faulty pottery. The description given for a classification of the quality of pottery ware. It signifies that the ware is well below the usual best standard, and not even good enough to fall within the description of seconds. But better than lump.

The description or classification of the quality of pottery ware - the eight (or more) grades of pottery quality:

- EXTRA BEST - Better than best quality. First first quality? But still not perfect perfect - see BEST.

- BEST - First quality pottery. Good ware. Sometimes called FIRSTS. But there is no such thing as a perfect pot since every piece will always have some sort of slight blemish - this is the very nature of pottery.

- BEST SECOND - Not bad enough to be a SECOND and not good enough to be best.

- SECONDS - Imperfect pottery. Not BEST and not THIRDS or LUMP! Slightly blemished or faulty and sold at a slight discount.

- WORST SECONDS - Sometimes called WORSER SECONDS. Slightly more imperfect than SECONDS. Then there was a DEGREE WORSER which was worse than WORST SECONDS. Or even WORSER WORSER. But not THIRDS, just yet.

- THIRDS - This signifies that the ware is well below the usual BEST standard, and not even good enough to fall within the description of SECONDS. But better than LUMP. The ware was/is still marketable, however, and was sold to hawkers or market stall holders for sale on the 'stones'. Badly twisted ware, crooked holloware, nipped ware and whirler plates fall into this category.

- LUMP - Massively faulty pottery. So bad that it is worse than WORSER SECONDS. Or even THIRDS. This is almost, but not quite, the lowest quality of ware that leaves any potbank, and usually it is ware that has just managed to escape being deliberately smashed. Whilst there may have been possibilities in some china shops of disposing of SECONDS, or even THIRDS the risk of dealing in LUMP is "too great to be incurred lightheartedly." Top-end, high-grade potbanks see to it that LUMP is sent to the shraff tip, "in spite of the fact that enquiries were freely received from the poorer districts or export for mixed grades of lump." Usually, about 100 years later, lump re-appears on TV shows as 'rare and valuable.' That’s irony!

- PITCHER Worse than lump. To be thrown away. Broken. Useless. But strangely saleable, at a price, in some quarters!

THIRTING Process. During ball clay mining. Cutting ball clay into blocks about 9 inches cube.

THIXOTROPY A description of the flow characteristics of clay slip. The property exhibited by the slip which becomes fluid when stirred or shaken and returns to the semi-solid state when standing.

THOB Potteries dialect word. Part of a bottle oven. The Hob. Just above the glut arch. "Put thee lobby on thob fur cape eat ot, duck." But note that it is not where you would cook breakfast. This was done directly on the fire, in the blazing mouth of the oven, using a British Standard No.8 shovel as the frying pan!

THOD Dialect word. Thump. Bump. Crunch. Bang. Wallop. Things that go bump in the night.

THOROUGH REPAIR Process. In a bottle oven. Almost a complete rebuild of the oven bottoms, ash pit and hob, bags and flues. Since production could be lost during a thorough repair then it was usually carried out at weekends.

THRAPE Thrash.

THREE-D PRINTING Not usually found on a potbank, just yet, but potbanks are getting to grips with the technology. (It can be found at Denby Pottery and have helped Burleigh Pottery to create a new mug shape. April 2014) This is stunning technology and perhaps holds the future of the industry. Ceramics are built up layer by layer using a specially-created and patented ceramic powder. They are then fired and glazed in the usual way.

This film shows how researchers at the Centre for Fine Print Research, Led by Professor Stephen Hoskins and his team, have developed new methods of creating ceramics using 3D printing technology and worked with Denby Potteries to test designs and develop prototype models in ceramics. ceramics are built up layer by layer using a specially-created -- and now patented - ceramic powder. They are then fired and glazed in the usual way.

THROW A potting process. Clay end. Method of shaping clay by hand on a revolving turntable.

THROW Collective noun for a group of potters' wheels. 'A throw of wheels.'

THROWER Occupation. Potting department. A craftsman who shapes pottery by hand from a lump of soft (plastic) clay which he throws on to the centre of a revolving potter's wheel. Origins date back long before the building of the Pyramids.

THROWING Process. Potting department. Clay end. Method of shaping pottery. A ball of wedged soft clay is thrown onto a revolving potters wheel, a turntable. Then it is centred and and worked into shape using plenty of water and the skill of the thrower's hands. The potter works the clay by compressing and extruding the clay in their hands to get it to the shape they require. Sometimes the pots are made taller, wider and thicker than the finished article because they will be turned. Clay shrinks up to 15% during the production process as water evaporates and as the piece is fired, so the potter has to allow for that and make the pot bigger than the finished piece.

back to top>

THROWING WHEEL Equipment. Also known as a potter's wheel, string wheel or great wheel. Clay end - potting department. A horizontal revolving disc on which wet clay is shaped into pots or other round ceramic objects. The machine used in the shaping of round clay pots before they are fired. The wheel may also be used during the process of fettling (trimming) the excess body from dried ware and for applying incised decoration or rings of colour.

3D Printing of Ceramics

This film shows how researchers at the Centre for Fine Print Research, Led by Professor Stephen Hoskins and his team, have developed new methods of creating ceramics using 3D printing technology and worked with Denby Potteries to test designs and develop prototype models in ceramics. ceramics are built up layer by layer using a specially-created -- and now patented - ceramic powder. They are then fired and glazed in the usual way.

THROW A potting process. Clay end. Method of shaping clay by hand on a revolving turntable.

THROW Collective noun for a group of potters' wheels. 'A throw of wheels.'

THROWER Occupation. Potting department. A craftsman who shapes pottery by hand from a lump of soft (plastic) clay which he throws on to the centre of a revolving potter's wheel. Origins date back long before the building of the Pyramids.

|

| Fred Halfpenny throwing. He worked for Josiah Wedgwood & Sons Ltd Mid 20th Century |

THROWING Process. Potting department. Clay end. Method of shaping pottery. A ball of wedged soft clay is thrown onto a revolving potters wheel, a turntable. Then it is centred and and worked into shape using plenty of water and the skill of the thrower's hands. The potter works the clay by compressing and extruding the clay in their hands to get it to the shape they require. Sometimes the pots are made taller, wider and thicker than the finished article because they will be turned. Clay shrinks up to 15% during the production process as water evaporates and as the piece is fired, so the potter has to allow for that and make the pot bigger than the finished piece.

Michael Casson, Craft of the Potter, BBC 1976

BBC Interlude 1950

back to top>

THROWING WHEEL Equipment. Also known as a potter's wheel, string wheel or great wheel. Clay end - potting department. A horizontal revolving disc on which wet clay is shaped into pots or other round ceramic objects. The machine used in the shaping of round clay pots before they are fired. The wheel may also be used during the process of fettling (trimming) the excess body from dried ware and for applying incised decoration or rings of colour.

|

| Spode's throwing wheel at Gladstone Pottery Museum Longton, Stoke-on-Trent. |

TIEING Process. During the placing of a bottle oven. Arch bungs of saggars are 'tied' to the crown of the oven by stuffing a fired saggar between the top of the bung and the underside of the crown of the oven to secure the bung.

TIE NO Dialect. Local administrative centre. "Thees too on em in Boslem, so seven in th'six tines!"

TIERCE A particular size of cask (42 gallons) used in the pottery industry for the packing and dispatch of pottery.

TICKLING Poking the firebed during firing to see (and judge) if it's OK.

TILE A thin slab of fired clay, sometimes decorated and/or glazed, used for various purposes, as to form one of the units of a roof covering, floor, or wall.

TILE MAKER Occupation. Potter. Maker of tiles.

TILE SETTER CRANK Kiln furniture used to support tiles during glost firing.

TILL Material. Type of clay. Boulder clay.

TIMPING Constantly making small adjustments to try to make improvements.

TIN Material used in glaze manufacture. Enhances lead glaze.

TIN GLAZE Type of glaze. A glaze made by adding tin oxide to lead glaze. When fired it becomes an opaque white colour. Much used in the production of maiolica and delftware.

TINNA Dialect meaning it isn't.

TINNA WOTH EAT Dialect. "Tinna woth eat!" meaning it isn't worth it.

TIPPIES Saggars. Equipment. Oval in shape. Saggars with a particular shape and used for a particular purpose in a bottle oven during firing. One of many different shapes. (Many thanks to Paul Niblett, long serving volunteer at Gladstone Pottery Museum, Longton, for sending this word which he sourced during conversations with the late Jack Jackson)

TIRED CLAY Pottery making problem. Created during throwing and caused by working the clay on the wheel for too long. The clay looses its structure and becomes un-workable and sloppy.

TISSUE Material. Printing shop. Decorating department. Very special thin tissue paper. Made locally for the pottery industry in Stoke-on-Trent, England.

TISSUE PULL A single print, on potters' tissue, pulled (ie printed) from an engraved copper plate but not passed on to the next stage of printing. Used as a trial or as an example to explain the process of transfer printing.

TITTIVATE Dialect. Smarten up.

TOBY JUG A pottery jug in the form of a seated person with knees showing. Jugs depicting just the head and shoulders of a figure are also referred to as Toby Jugs, although these should strictly be called Character Jugs. Toby Jugs first made about 1740 and owed their name to Toby Philpot, a notorious drinker, and the subject of the song 'The Brown Jug.'

back to top>

TOE RAG or TOW RAG Dialect. An oatcake.

OR

TOE RAG - rag wrapped around the toes to absorb sweat e.g. when standing all day by a kiln, or kill. Also used as a term of abuse as in 'he's a bloody toe rag'. (Word courtesy of Mick Green and his Mum).

TOE RATE Dialect. Are you ok?

TOOL FILER Occupation. Fitting shop or potting department. Makes the metal profile tools which fit to a monkey arm and which form the back of a piece of flatware on a jigger. He also makes the profile for cup and holloware making.

TOILET A potting masterpiece! "A useful contrivance, the purpose of which requires no explanation" GEORGE JENNINGS, 1877 - English sanitary engineer and plumber who invented the first public flush toilets.

TOILET WARE Name given to the pottery used for the daily ablutions - used before the introduction of plumbed-in bathroom equipment. Different 'compositions' were available e.g. five piece toilet set, six piece toilet set, double toilet set, and eleven piece American toilet set. These sets contained ewer and basin or bowl, chamber (pot) or covered chamber, slop pail, soap dish, brush tray, brush vase and stand, sponge, jug and mug .

TIERCE A particular size of cask (42 gallons) used in the pottery industry for the packing and dispatch of pottery.

TICKLING Poking the firebed during firing to see (and judge) if it's OK.

TILE A thin slab of fired clay, sometimes decorated and/or glazed, used for various purposes, as to form one of the units of a roof covering, floor, or wall.

TILE MAKER Occupation. Potter. Maker of tiles.

TILE SETTER CRANK Kiln furniture used to support tiles during glost firing.

TILL Material. Type of clay. Boulder clay.

TIMPING Constantly making small adjustments to try to make improvements.

TIN Material used in glaze manufacture. Enhances lead glaze.

TIN GLAZE Type of glaze. A glaze made by adding tin oxide to lead glaze. When fired it becomes an opaque white colour. Much used in the production of maiolica and delftware.

TINNA Dialect meaning it isn't.

TINNA WOTH EAT Dialect. "Tinna woth eat!" meaning it isn't worth it.

TIPPIES Saggars. Equipment. Oval in shape. Saggars with a particular shape and used for a particular purpose in a bottle oven during firing. One of many different shapes. (Many thanks to Paul Niblett, long serving volunteer at Gladstone Pottery Museum, Longton, for sending this word which he sourced during conversations with the late Jack Jackson)

TIRED CLAY Pottery making problem. Created during throwing and caused by working the clay on the wheel for too long. The clay looses its structure and becomes un-workable and sloppy.

TISSUE Material. Printing shop. Decorating department. Very special thin tissue paper. Made locally for the pottery industry in Stoke-on-Trent, England.

TISSUE PULL A single print, on potters' tissue, pulled (ie printed) from an engraved copper plate but not passed on to the next stage of printing. Used as a trial or as an example to explain the process of transfer printing.

|

| Tissue pull |

TITTIVATE Dialect. Smarten up.

TOBY JUG A pottery jug in the form of a seated person with knees showing. Jugs depicting just the head and shoulders of a figure are also referred to as Toby Jugs, although these should strictly be called Character Jugs. Toby Jugs first made about 1740 and owed their name to Toby Philpot, a notorious drinker, and the subject of the song 'The Brown Jug.'

|

| Toby Jug, with his knees |

back to top>

TOE RAG or TOW RAG Dialect. An oatcake.

OR

TOE RAG - rag wrapped around the toes to absorb sweat e.g. when standing all day by a kiln, or kill. Also used as a term of abuse as in 'he's a bloody toe rag'. (Word courtesy of Mick Green and his Mum).

TOE RATE Dialect. Are you ok?

TOOL FILER Occupation. Fitting shop or potting department. Makes the metal profile tools which fit to a monkey arm and which form the back of a piece of flatware on a jigger. He also makes the profile for cup and holloware making.

TOILET A potting masterpiece! "A useful contrivance, the purpose of which requires no explanation" GEORGE JENNINGS, 1877 - English sanitary engineer and plumber who invented the first public flush toilets.

TOILET WARE Name given to the pottery used for the daily ablutions - used before the introduction of plumbed-in bathroom equipment. Different 'compositions' were available e.g. five piece toilet set, six piece toilet set, double toilet set, and eleven piece American toilet set. These sets contained ewer and basin or bowl, chamber (pot) or covered chamber, slop pail, soap dish, brush tray, brush vase and stand, sponge, jug and mug .

|

| Toilet set combinations from Spode |

|

| Spode 1902 catalogue |

TOOL FILER Occupation. Fitting shop or potting department. Makes the metal profile tools which fit to a monkey arm and which form the back of a piece of flatware on a jigger. He also makes the profile for cup and holloware making.

TOP HAT KILN Equipment. Intermittent kiln. Ware is placed on a non-movable refractory setting. Then a box-shaped hood (the top hat) is lowered over the setting. Electric or gas burners within the structure of the top hat are then used to raise the temperature inside to fire the ware. Invented By Donald Shelley. In 1956 Shelley Electric Furnaces Ltd. was formed to manufacture top hat kilns for use by Shelley and for sale to other potteries. Installed at Spode, Stoke-on-Trent in 1957.

TOPPING OFF Process in the potting department - casting shop. Removal, with a knife blade, of the surplus clay, which has set around the top of a plaster of Paris mould after casting. Then smoothing what will be the top inner rim of the cast vessel with a knife, rough cloth and damp sponge.

TOPPING STICK Equipment. Used by the saggar maker when bannering. A small metal or wooden tool shaped like a small cricket bat used to true up the rim of a freshly made unfired saggar to ensure that it lay in one true horizontal plane. Bungs of saggars in a bottle oven can reach up to 20 feet high, and should stack as close to the vertical as possible. It was therefore an important job to ensure that the rims and bottoms of freshly made saggars were perfectly flat.

|

| A saggar maker using a topping stick to banner his saggar |

TOPPING TOOL Flat tool used by the saggar maker to cut the top edge of the clay saggar while the drum is still in position.

TOP OFF Part of the baiting process. Using the back of a shovel to level the fuel bed in the firemouth.

TOPS The top most saggars in the bottle oven. Two men would 'draw the tops' when a recently fired bottle oven was emptied. It was extremely hot and strenuous work and they would do it in half hour stretches. Those who had drawn the tops would be let off doing any climbing on osses during the following setting (or placing) of the oven.

TORTOISESHELL Decoration. Underglaze. Created by sponging coloured ceramic powder or slip onto biscuit ware so that when glazed and fired the colours ran and blended together at high temperature with the soft glaze creating a tortoiseshell effect. This kind of decoration was popular from the 1740s to the 1780s.

TOUCHER Occupation. Common in the sanitaryware manufacturing industry. Often the casters will help each other out when casting large, heavy or complicated pieces. For instance when box rim closets are being cast, the rim of the closet is made separately from the base. The two parts are then stuck together using monkey muck. The top rim, in its clay state, is very soft and needs extra support as it is lowered down onto the base (which is fully supported in its original plaster of Paris mould.) The caster will call for help from his toucher "Ayup, give us a touch, mate!" In the photo below the toucher is on the left and the caster is on the right.

TOW Material used during the process. Pronounced 'toe.' A type of hairy sisal fibre, a bi-product of rope making. A plant fibre with the consistency of horse hair.

TOP OFF Part of the baiting process. Using the back of a shovel to level the fuel bed in the firemouth.

TOPS The top most saggars in the bottle oven. Two men would 'draw the tops' when a recently fired bottle oven was emptied. It was extremely hot and strenuous work and they would do it in half hour stretches. Those who had drawn the tops would be let off doing any climbing on osses during the following setting (or placing) of the oven.

TORTOISESHELL Decoration. Underglaze. Created by sponging coloured ceramic powder or slip onto biscuit ware so that when glazed and fired the colours ran and blended together at high temperature with the soft glaze creating a tortoiseshell effect. This kind of decoration was popular from the 1740s to the 1780s.

TOUCHER Occupation. Common in the sanitaryware manufacturing industry. Often the casters will help each other out when casting large, heavy or complicated pieces. For instance when box rim closets are being cast, the rim of the closet is made separately from the base. The two parts are then stuck together using monkey muck. The top rim, in its clay state, is very soft and needs extra support as it is lowered down onto the base (which is fully supported in its original plaster of Paris mould.) The caster will call for help from his toucher "Ayup, give us a touch, mate!" In the photo below the toucher is on the left and the caster is on the right.

TOW Material used during the process. Pronounced 'toe.' A type of hairy sisal fibre, a bi-product of rope making. A plant fibre with the consistency of horse hair.

TOWER Occupation. Clay end. Potting department. Usually female.

TOWING Process. Clay end. Usually carried out by a female. She removes the rough seams or edges of dry, jiggered flatware (plates, saucers) by placing the piece on a fast rotating wheel and using various (sometimes homemade) tools including a polished hacksaw blade, sandpaper or more importantly tow to smooth down the edges. Clouds of dangerous clay dust is created and this needs to be sucked away by extractor fans in a booth. Awful job. Deadly in fact.

TOW CRATE Dialect. Correct speech. Pronounced 'toe crate.'

TOW RAG Dialect. Oatcake.

TOW WICK Material used in the process. Clay end. Nothing to do with an oatcake.

TRACE Decoration. A slender gold or coloured line. Free-hand painted onto the handle of a teacup, jug, teapot or other holloware. Also known as fully traced. But see half traced - the trace only goes half way - obviously.

TRACER Occupation. Decorating department. See tracing.

TRACING Process. The application of a slender decorative line (usually in gold) onto holloware handles.

TRADE SIZES This is complicated! Read on. The Staffordshire pottery industry had a uniquely peculiar system for describing the sizes of its products. To an outsider and the uninitiated, it was complicated, messy, inconsistent and arbitrary. To those in the know, a manufacturer and his workers, it was easy to understand but skewed to the benefit of the boss.

The nominal Trade sizes of flatware, such as plates and dishes, differ from the Actual sizes in inches. For example, a Trade 8" plate usually measures Actual 9" and a Trade 10" plate measures Actual 10.5” or more. Similarly, a 16" Trade oval meat dish would truly measure 18" Actual and the whole nest of dishes will be greater in Actual size than the nominal Trade size.

But, probably, the most perplexing point is encountered in connection with holloware. Jugs. teapots, pudding owls and the like are described under trade terms such as 24s, 30s and 36s, each gradation occurring in spans of sixes. And the smaller the number the larger the size of piece! The full range of Trade Sizes was 6s, 12s, 18s, 24s, 30s, 36s, 42s, 48s, 54s, and 60s.

The underlying principle of this arrangement appears to have come down through the generations, and the apparent inconsistencies are accounted for by the fact that originally, pottery was sold by the basket, in what were known as "warehouse dozens.”

The large size jug or teapot or bowl would be twelve to the dozen, and called a "12s"; the next smaller size would be eighteen to the dozen, and styled an "18s"; the pint size would be twenty-four to the dozen, and called a "24s" and so on down or up the scale. To add to the confusion, one manufacturer's sizes do not necessarily conform with those of other manufacturers; the shapes may be modelled to bigger or smaller capacities.

During the early 20th Century the system was changed and articles were sold in dozens of twelve, yet the old method of describing the sizes persisted well into the 1990s.

TRAILING Process. Method of decoration. Slip trailing.

TRANSFER The printed sheet of transfer paper used in Transfer Printing. See below

TRANSFERER (Sometimes spelled TRANSFERRER) Occupation. Decorating end. Pronounced either as TRANS-FUR-RER or TRANS-FARE-RER depending on the individual potbank or the Potteries town. The person (most likely a female) who decorates pottery using transfers produced by the transfer printing process. See directly below.

TRANSFER PRINTING Process. Decorating Department. The transfer of a monochrome decorative surface pattern to a piece of pottery from an engraved copper plate filled with colour (a mixture of metallic oxides, fluxes and printing oils) using specially prepared potters' thin transfer tissue paper.

The decorative pattern is first engraved onto a flat sheet of copper (the copper plate). The engraved lines are filled with colour, (a mixture of metallic oxides, fluxes and printing oils) then a specially sized tissue paper (the paper is pasted with soft soap solution) is pressed onto the copper plate. The colour transfers from the copper to the paper which is then placed coloured side down into position on the pottery piece. The paper is rubbed hard and the pattern transfers from the paper to the pot. The piece is then washed in water to float off the paper, leaving the pattern behind. After a hardening on firing, then dipping and glost firing, the decoration becomes permanent.

Transfer printed images can be applied on top of the glazed pot (on-glaze) or under the glaze on the biscuit ware before dipping and glost fire (under-glaze).

2013 update | Burleigh (Burgess and Leigh at Middleport Pottery near Burslem in Stoke-on-Trent) is one of the last remaining potters in the world to use the traditional skill of underglaze transfer printing. Whereas most modern patterns are applied using water slide decal or litho, at Burleigh patterns are created using hand engraved copper rollers, an art now only done by a few highly skilled men. The rollers are placed in roller presses where the ink - ceramic colour - is added and pressed against them to create the print on the tissue. The tissue is carefully cut and rubbed onto the pot by the transferer with soft soap, before being washed off to leave the pattern on the biscuit piece. After hardening on the pot is dipped in glaze and fired leaving the transfer print underneath the glaze to ensure that the pattern never wears off.

TRACING Process. The application of a slender decorative line (usually in gold) onto holloware handles.

TRADE SIZES This is complicated! Read on. The Staffordshire pottery industry had a uniquely peculiar system for describing the sizes of its products. To an outsider and the uninitiated, it was complicated, messy, inconsistent and arbitrary. To those in the know, a manufacturer and his workers, it was easy to understand but skewed to the benefit of the boss.

The nominal Trade sizes of flatware, such as plates and dishes, differ from the Actual sizes in inches. For example, a Trade 8" plate usually measures Actual 9" and a Trade 10" plate measures Actual 10.5” or more. Similarly, a 16" Trade oval meat dish would truly measure 18" Actual and the whole nest of dishes will be greater in Actual size than the nominal Trade size.

But, probably, the most perplexing point is encountered in connection with holloware. Jugs. teapots, pudding owls and the like are described under trade terms such as 24s, 30s and 36s, each gradation occurring in spans of sixes. And the smaller the number the larger the size of piece! The full range of Trade Sizes was 6s, 12s, 18s, 24s, 30s, 36s, 42s, 48s, 54s, and 60s.

The underlying principle of this arrangement appears to have come down through the generations, and the apparent inconsistencies are accounted for by the fact that originally, pottery was sold by the basket, in what were known as "warehouse dozens.”

The large size jug or teapot or bowl would be twelve to the dozen, and called a "12s"; the next smaller size would be eighteen to the dozen, and styled an "18s"; the pint size would be twenty-four to the dozen, and called a "24s" and so on down or up the scale. To add to the confusion, one manufacturer's sizes do not necessarily conform with those of other manufacturers; the shapes may be modelled to bigger or smaller capacities.

During the early 20th Century the system was changed and articles were sold in dozens of twelve, yet the old method of describing the sizes persisted well into the 1990s.

TRAILING Process. Method of decoration. Slip trailing.

TRANKLIMENTS sometimes also TRANKLEMENTS Dialect. Trinkets, bits of jewellery, personal items of small value. Small possessions and paraphernalia. Also, sometimes, the small tool parts that fit a vacuum cleaner. (Many thanks go to Joan Salmon, for suggesting this word. June 2016).

TRANSFER The printed sheet of transfer paper used in Transfer Printing. See below

TRANSFERER (Sometimes spelled TRANSFERRER) Occupation. Decorating end. Pronounced either as TRANS-FUR-RER or TRANS-FARE-RER depending on the individual potbank or the Potteries town. The person (most likely a female) who decorates pottery using transfers produced by the transfer printing process. See directly below.

TRANSFER PRINTING Process. Decorating Department. The transfer of a monochrome decorative surface pattern to a piece of pottery from an engraved copper plate filled with colour (a mixture of metallic oxides, fluxes and printing oils) using specially prepared potters' thin transfer tissue paper.

The decorative pattern is first engraved onto a flat sheet of copper (the copper plate). The engraved lines are filled with colour, (a mixture of metallic oxides, fluxes and printing oils) then a specially sized tissue paper (the paper is pasted with soft soap solution) is pressed onto the copper plate. The colour transfers from the copper to the paper which is then placed coloured side down into position on the pottery piece. The paper is rubbed hard and the pattern transfers from the paper to the pot. The piece is then washed in water to float off the paper, leaving the pattern behind. After a hardening on firing, then dipping and glost firing, the decoration becomes permanent.

Transfer printed images can be applied on top of the glazed pot (on-glaze) or under the glaze on the biscuit ware before dipping and glost fire (under-glaze).

|

| Transferers at Burleigh Pottery 2013 |

2013 update | Burleigh (Burgess and Leigh at Middleport Pottery near Burslem in Stoke-on-Trent) is one of the last remaining potters in the world to use the traditional skill of underglaze transfer printing. Whereas most modern patterns are applied using water slide decal or litho, at Burleigh patterns are created using hand engraved copper rollers, an art now only done by a few highly skilled men. The rollers are placed in roller presses where the ink - ceramic colour - is added and pressed against them to create the print on the tissue. The tissue is carefully cut and rubbed onto the pot by the transferer with soft soap, before being washed off to leave the pattern on the biscuit piece. After hardening on the pot is dipped in glaze and fired leaving the transfer print underneath the glaze to ensure that the pattern never wears off.

2023 update | Burleigh (Burgess and Leigh at Middleport Pottery) claim that they are the only manufacturer in the world still using the tissue transfer technique. More here> https://www.stokesentinel.co.uk/news/stoke-on-trent-news/gallery/last-pottery-factory-using-traditional-8821980

PLUCK and DUST, sometimes called PULL and DUST This is a variant to the process described above. The mixture of colour pigment and oil which is spread over the surface of the copper plate, prior to printing the design, has a low percentage colour content. Subsequently the engraved design which had been transferred to the pot needed strengthening. Once the tissue paper had been peeled off the pot, powdered pigment was lightly dusted onto it. The pigment stuck to the sticky, oily design.

TRANSFERRING (Sometimes spelled transfering) The process of transfer printing. In the movie below an engraved copper cylinder (rather than an engraved flat copper plate) is used to create the transfer. (The video below will work - Click on Learn More, if it appears, and you will get the Vimeo video.

back to top>

TRANSFERWARE Decorated pottery with a pattern that has been applied by transfering that pattern onto its surface. The pattern is originally engraved onto a copper plate, the engraved lines are filled with ceramic colour, then a specially sized paper is pressed onto the copper plate. The colour transfers to the paper which is then placed coloured side down into position on the pottery piece. The paper is rubbed hard and the pattern transfers from the paper to the pot. The piece is then washed in water to float off the paper, leaving the pattern behind. After hardening on, dipping and firing the decoration becomes permanent. See engraving here>

TRANSLUCENT and TRANSLUCENCY The shadow of your hand can be seen through the piece when it is held to a bright light. Bone china and some porcelains are translucent.

TRASHERS Dialect. Sometimes called TRASHES. 'Owd shooze'. Tatty old shoes, boots or slippers. Worn in the potbank shop - a workshop not a sales shop.

TREMBLEUSE Interesting word but not usually found on a potbank. In fact very rarely heard today in the industry. At all. But probably more commonly used in museums. Name of a no-spill cup & saucer combination designed for those people who suffered from the shakes. The cup fits into an elevated rim in the centre of a saucer. This word was submitted to Potbank Dictionary by Ian Davenport. Thank you.

TRIAL A sample of ware which can be drawn out of the bottle oven during firing and examined by the fireman to judge its progress (See also pyroscope and Bullers ring).

TRIALS Small samples of pot or pyroscopes specially formulated and placed in the bottle oven prior to firing. At intervals during the fire these could be withdrawn through the trial holes and measured. This enabled the fireman to follow the progress of the firing.

TRIAL HOLES Part of a bottle oven. Small holes built in to the walls of a bottle oven through which the fireman and his sitter up can reach through to parts of the oven as it is being fired to remove trial pieces such as Bullers Rings.

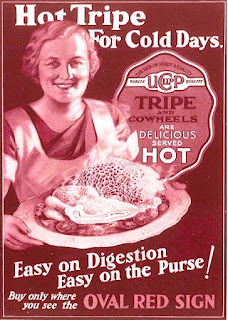

TRIPE Food. Popular with Potteries people. The lining of the ox stomach. Bleached and partially cooked before being sold. Requires further cooking for a further two hours before eating. Unbleached tripe was/is also available!

TRIPE A fictitious and ridiculous story. Bull! "Ay towks a lood a tripe, ay does!"

TRIPE & ONIONS Food for the potter. Inexpensive and filling. Tripe is the stomach lining of an ox; the first stomach's lining is called blanket, the second honeycomb and the third thick seam. They all taste the same, only the appearance is different. Tripe should always be sold dressed and parboiled.

TRUCK Payment for work done in the from of old clothes or goods. Common in the mid eighteenth century but condemned by the Unions during the nineteenth century.

TUB THUMPER Occupation. Warehouse department. Cooper. Maker of wooden casks (similar to giant beer barrels) as containers for pottery, packed tightly with either straw or woodwool, prior to dispatch.

TUBE LINED Thin trails of slip squeezed and piped from the nozzle of a handheld rubber bulb to form raised lines of decoration which separate areas of coloured glazes. Made famous and popular by Moorcroft Pottery.

TUBE LINING Process. A decorating technique where soft clay is squeezed from a bag or rubber bulb via a fine tube onto the body of a pot. This creates an outline for a design that can later be enhanced by further painted decoration.

back to top>

TUFF SHIT Slang. Hard luck. 'Hard lines.'

TUFF TOM Material. Marl clay.

TUGGIES Dialect. Lice.

TUN DISH Funnel.

TUNNEL Entrance to a potbank. Covered tunnel wide and high enough for a horse and cart. With huge wooden gates on the road side. Connects the potbank yard with the main road. One of the longest in the Potteries can still be seen at Gladstone Pottery Museum, Longton, Stoke-on-Trent.

TUNNEL KILN Equipment. 'Modern' kiln used for the continuous firing of pottery. About 100 yards long. Cold at the entrance and cold at the exit but in the middle is the firing zone. Trucks containing product are pushed through the firing chamber as a 'train.'

TURNER Occupation. Potting department. Clay end. Male or female but usually male. See below.

TURNERS LATHE Equipment. Potting Department. Similar to a woodworker's lathe. The turner shapes and shaves the thrown clay piece on the lathe using a steel tool to carve away at the semi hard clay. The lathe shaft may be rotated in either a clockwise or anticlockwise direction.

TURNING Process. Potting department. When a pot has been thrown and dried to a leather-hard or cheese-hard state it can be shaped further by putting it back on the wheel or onto a horizontal lathe and turned using a sharp metal tool. Just as wood or metal can be shaped on a lathe the cheese-hard clay can be turned and cut into perfectly symmetrical items using a variety of tools.

TURNING POLE Equipment. Used by modelers and mould makers to steady their hand during modelling and turning.

TURPS Material. Turpentine. Used in the decorating end and mixed with colours during decoration.

TWADDELL A system for denoting the specific gravity of a liquid. Twaddell Degrees. Eg for Sodium Silicate - a component of pottery slip.

TWIFFLER or TWIFLER or TWYFLER Similar to a muffin. A small plate.

TYG A pot. Old name for multi-handled drinking vessel designed to be passed amongst drinkers. A large English pottery cup or mug with three or more handles dividing the rim into sections for several drinkers. May be tall, black-glazed, red-bodied drinking vessels produced from the 15th century through the first half of the 17th century, peaking in popularity during the 16th and 17th centuries. Multiple handles allow hot drinks to be passed around without pain! In the Last Bottle Oven Firing in 1978 a two-handled version was made but still called a tyg.

Hot press, flat plate, printing and transferring at Spode

These are the principal stages required in producing an engraved decorative design - from the application of the colour to the engraved copper plate, through to the glost firing of the pottery piece.- An engraved copper plate, containing the decorative design, is warmed over a hot stove, sometimes called a backstun.

- Ceramic colour (a mixture of ceramic pigment and thick sticky oil) is spread over the surface of the copper plate and rubbed into the engraved lines with a wooden dabber. Because the copper plate had been warmed the oil mixture flows more easily into the engraving.

- Most of the excess colour is carefully scraped/wiped off the copper plate.

- The copper is bossed to remove the last remains of excess colour from the surface leaving the colour only in the engraved design.

- Damp, special, tissue paper, previously 'sized' with soft soap and water, is placed on the copper plate.

- The copper and the paper are rolled through a press, together. The roller, on the press, is covered with felt, which helps to force the paper into the engraving.

- The coloured design becomes transferred from the copper to the tissue.

- The copper plate is warmed on the stove again and the tissue paper print is carefully peeled away from the plate. As it is peeled away the tissue takes with it the colour from the engraving. This is called a pull.

- The parts of the print required for each part of each pot are carefully cut from the printed tissue paper pull.

- The paper transfer is skillfully applied to the biscuit fired pot. Centres are applied first, borders afterwards. The tissue is rubbed into place

- The tissue pull, having been rubbed down vigorously onto the pot, using a stiff bristled brush and soft soap, is then washed off with water leaving only the printed image behind on the surface of the pot.

- The print is hardened on in a low temperature firing of about 650-700°C.

- The pot is dipped in glaze. The hardening on enables the piece to be glazed without damaging the decoration.

- The pot is finally fired to 1070°C in the glost oven. The silica in the glaze reacts with the cobalt colour of the decoration to create Spode’s world famous lustrous blue.

PLUCK and DUST, sometimes called PULL and DUST This is a variant to the process described above. The mixture of colour pigment and oil which is spread over the surface of the copper plate, prior to printing the design, has a low percentage colour content. Subsequently the engraved design which had been transferred to the pot needed strengthening. Once the tissue paper had been peeled off the pot, powdered pigment was lightly dusted onto it. The pigment stuck to the sticky, oily design.

TRANSFERRING (Sometimes spelled transfering) The process of transfer printing. In the movie below an engraved copper cylinder (rather than an engraved flat copper plate) is used to create the transfer. (The video below will work - Click on Learn More, if it appears, and you will get the Vimeo video.

///

back to top>

TRANSFERWARE Decorated pottery with a pattern that has been applied by transfering that pattern onto its surface. The pattern is originally engraved onto a copper plate, the engraved lines are filled with ceramic colour, then a specially sized paper is pressed onto the copper plate. The colour transfers to the paper which is then placed coloured side down into position on the pottery piece. The paper is rubbed hard and the pattern transfers from the paper to the pot. The piece is then washed in water to float off the paper, leaving the pattern behind. After hardening on, dipping and firing the decoration becomes permanent. See engraving here>

TRANSLUCENT and TRANSLUCENCY The shadow of your hand can be seen through the piece when it is held to a bright light. Bone china and some porcelains are translucent.

|

| Translucent Bone China |

TRASHERS Dialect. Sometimes called TRASHES. 'Owd shooze'. Tatty old shoes, boots or slippers. Worn in the potbank shop - a workshop not a sales shop.

TREMBLEUSE Interesting word but not usually found on a potbank. In fact very rarely heard today in the industry. At all. But probably more commonly used in museums. Name of a no-spill cup & saucer combination designed for those people who suffered from the shakes. The cup fits into an elevated rim in the centre of a saucer. This word was submitted to Potbank Dictionary by Ian Davenport. Thank you.

|

| Du Paquier Porcelain Manufactory Austrian, Vienna, about 1740 Image courtesy of Getty's Open Content Program |

TRIAL A sample of ware which can be drawn out of the bottle oven during firing and examined by the fireman to judge its progress (See also pyroscope and Bullers ring).

TRIALS Small samples of pot or pyroscopes specially formulated and placed in the bottle oven prior to firing. At intervals during the fire these could be withdrawn through the trial holes and measured. This enabled the fireman to follow the progress of the firing.

TRIAL HOLES Part of a bottle oven. Small holes built in to the walls of a bottle oven through which the fireman and his sitter up can reach through to parts of the oven as it is being fired to remove trial pieces such as Bullers Rings.

TRIPE Food. Popular with Potteries people. The lining of the ox stomach. Bleached and partially cooked before being sold. Requires further cooking for a further two hours before eating. Unbleached tripe was/is also available!

TRIPE & ONIONS Food for the potter. Inexpensive and filling. Tripe is the stomach lining of an ox; the first stomach's lining is called blanket, the second honeycomb and the third thick seam. They all taste the same, only the appearance is different. Tripe should always be sold dressed and parboiled.

TRUCK Payment for work done in the from of old clothes or goods. Common in the mid eighteenth century but condemned by the Unions during the nineteenth century.

TUB THUMPER Occupation. Warehouse department. Cooper. Maker of wooden casks (similar to giant beer barrels) as containers for pottery, packed tightly with either straw or woodwool, prior to dispatch.

|

| Pottery Casks (tubs) packed with ware on their way to market |

TUBE LINED Thin trails of slip squeezed and piped from the nozzle of a handheld rubber bulb to form raised lines of decoration which separate areas of coloured glazes. Made famous and popular by Moorcroft Pottery.

TUBE LINING Process. A decorating technique where soft clay is squeezed from a bag or rubber bulb via a fine tube onto the body of a pot. This creates an outline for a design that can later be enhanced by further painted decoration.

|

| Moorcroft Pottery - an example of tube lining |

back to top>

TUFF SHIT Slang. Hard luck. 'Hard lines.'

TUFF TOM Material. Marl clay.

TUGGIES Dialect. Lice.

TUN DISH Funnel.

TUNNEL Entrance to a potbank. Covered tunnel wide and high enough for a horse and cart. With huge wooden gates on the road side. Connects the potbank yard with the main road. One of the longest in the Potteries can still be seen at Gladstone Pottery Museum, Longton, Stoke-on-Trent.

|

| Tunnel entrance from the yard at Gladstone Pottery Museum Before restoration Early 1970 |

TUNNEL KILN Equipment. 'Modern' kiln used for the continuous firing of pottery. About 100 yards long. Cold at the entrance and cold at the exit but in the middle is the firing zone. Trucks containing product are pushed through the firing chamber as a 'train.'

TURNER Occupation. Potting department. Clay end. Male or female but usually male. See below.

TURNERS LATHE Equipment. Potting Department. Similar to a woodworker's lathe. The turner shapes and shaves the thrown clay piece on the lathe using a steel tool to carve away at the semi hard clay. The lathe shaft may be rotated in either a clockwise or anticlockwise direction.

TURNING Process. Potting department. When a pot has been thrown and dried to a leather-hard or cheese-hard state it can be shaped further by putting it back on the wheel or onto a horizontal lathe and turned using a sharp metal tool. Just as wood or metal can be shaped on a lathe the cheese-hard clay can be turned and cut into perfectly symmetrical items using a variety of tools.

TURNING POLE Equipment. Used by modelers and mould makers to steady their hand during modelling and turning.

TURPS Material. Turpentine. Used in the decorating end and mixed with colours during decoration.

TWADDELL A system for denoting the specific gravity of a liquid. Twaddell Degrees. Eg for Sodium Silicate - a component of pottery slip.

TWIFFLER or TWIFLER or TWYFLER Similar to a muffin. A small plate.

TYG A pot. Old name for multi-handled drinking vessel designed to be passed amongst drinkers. A large English pottery cup or mug with three or more handles dividing the rim into sections for several drinkers. May be tall, black-glazed, red-bodied drinking vessels produced from the 15th century through the first half of the 17th century, peaking in popularity during the 16th and 17th centuries. Multiple handles allow hot drinks to be passed around without pain! In the Last Bottle Oven Firing in 1978 a two-handled version was made but still called a tyg.